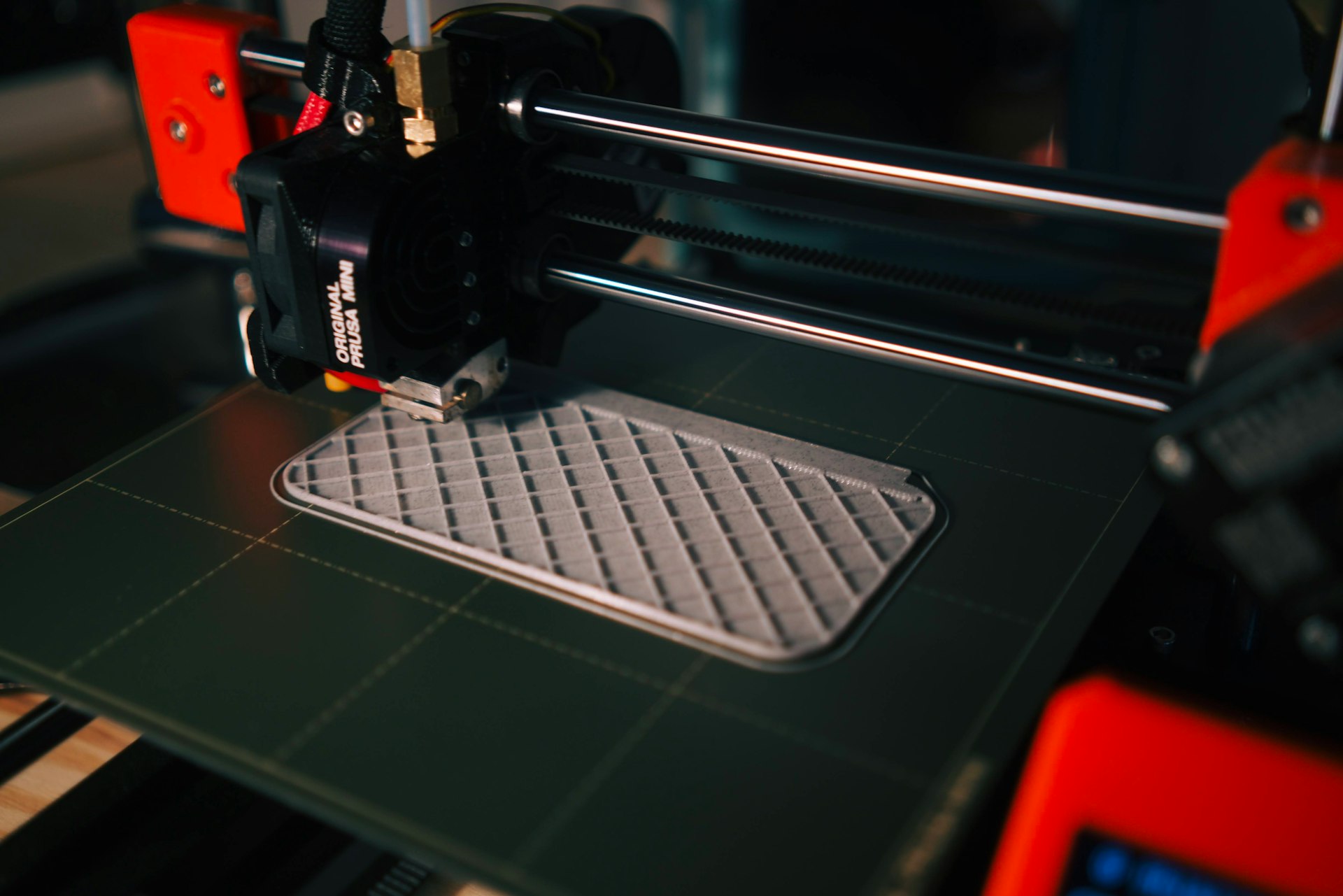

FDM 3D Printing

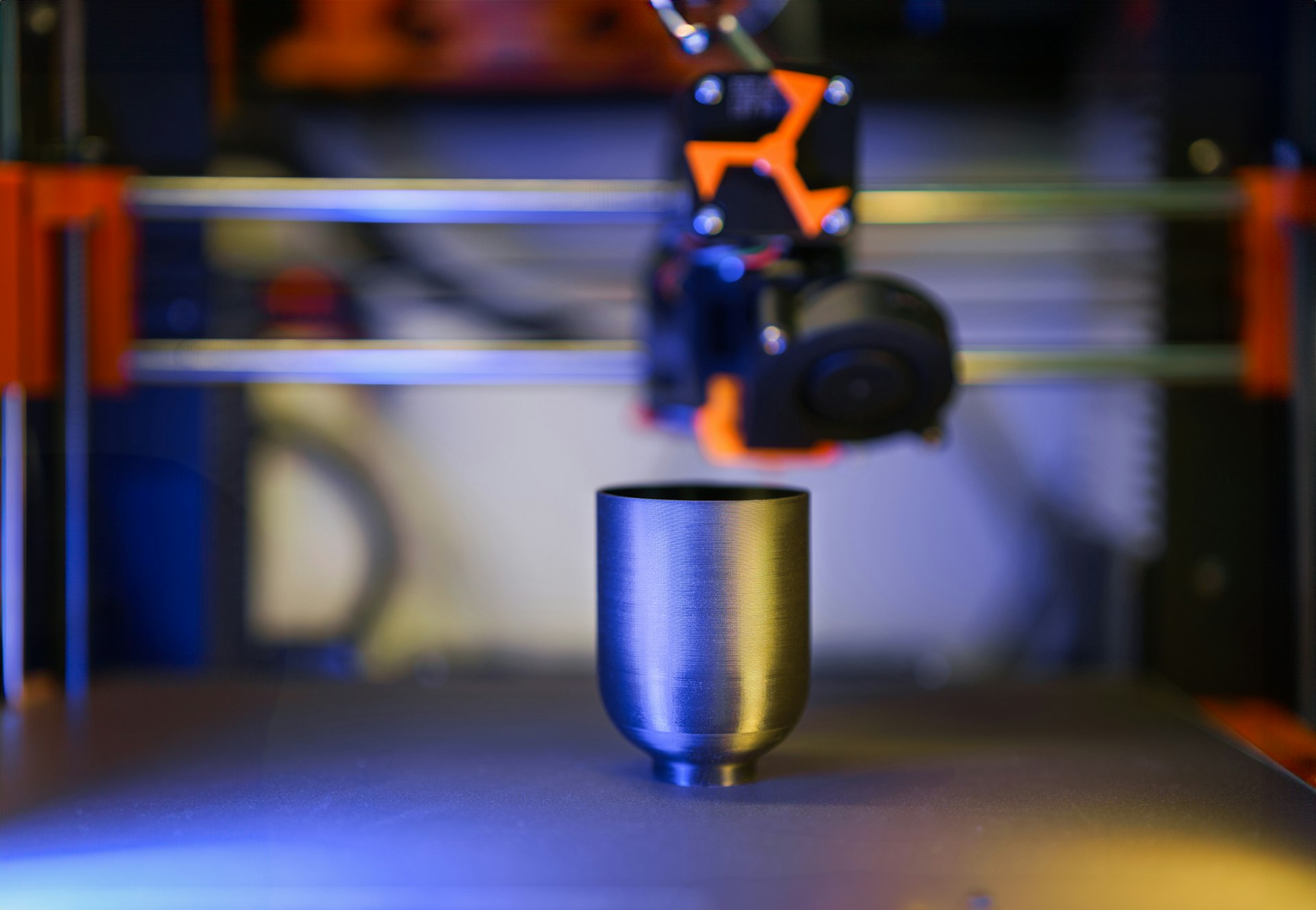

Compared to traditional plastic manufacturing like injection molding and resin 3D printing, FDM (filament-based) 3D printing offers a more sustainable path—especially when combined with recycling. Injection molding produces large volumes efficiently but relies on expensive molds, high energy input, and often results in excess material waste like sprues and runners. Resin 3D printing creates high-detail parts but uses toxic, non-recyclable resins that require careful disposal and generate chemical waste. In contrast, FDM 3D printing produces less waste per part, can use biodegradable or recycled materials, and allows for local, on-demand production. With closed-loop recycling, it becomes one of the most environmentally conscious plastic-making methods available.

FDM 3D Printing - Advantages

Minimal Fumes

Other manufacturing processes, like SLA 3D printing (resin-based) will create toxic fumes in the process. FDM printing's emissions are minimal and safe if handled properly.

Additive Manufacturing

FDM 3D printing, a branch of additive manufacturing (AM), minimalizes waste because only material needed is used (unlike subtractive manufacturing - CNC machining)

Minimal Waste

Unlike injection molding that requires a mold, FDM 3D printing (filament based) can create infinite variations of an object without needed a pre-made mold, cutting down on the waste generated.

Low Waste

Out of our oceans!

Design Freedom

Make it how you like it!

Material Efficiency

Only where you need it!

Community

Focus

Accessible to all!