Material Choices

Our material choices prioritize environmental responsibility at every step. We focus on using plastics that are renewable, biodegradable, and easily recyclable to minimize waste and pollution. PLA stands out as our best option because it’s made from plant-based resources, breaks down more safely than traditional plastics, and performs well in 3D printing. By committing to eco-friendly materials like PLA, we reduce our carbon footprint and support a more sustainable manufacturing cycle.

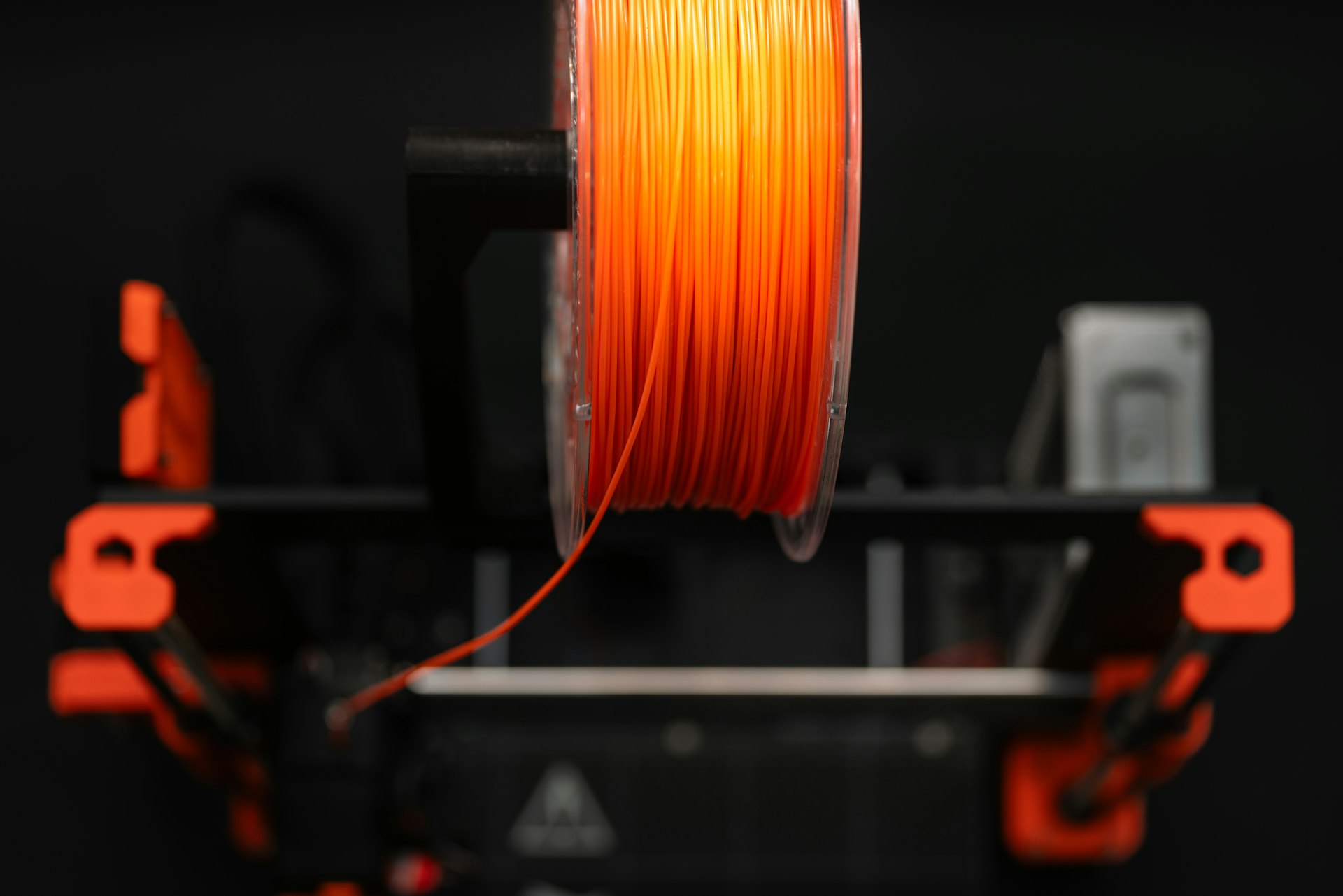

PLA Filament

Ease-of-Use

PLA is easy to print with due to low temperatures, minimal warping, and no heated bed needed. It’s beginner-friendly and delivers consistent results.

Plant-Based

PLA is made from renewable plant materials like corn starch, making it a sustainable alternative to petroleum-based plastics.

Eco-Friendly

PLA is eco-friendly and biodegradable under industrial composting conditions, breaking down into harmless natural elements.

*Nothing is forever...

While recycling PLA into 3D printer filament is a powerful step toward sustainability, it’s important to understand that plastics like PLA can’t be recycled indefinitely. Each time PLA is heated, melted, and re-extruded, its long molecular chains—responsible for strength and flexibility—begin to break down. Over multiple cycles, this degradation leads to filament that is more brittle, less reliable, and prone to print failures. In most cases, PLA can be effectively recycled two to three times before its quality drops too far for high-performance prints.

That said, there are smart ways to stretch the life of recycled PLA. One method is to blend it with a portion of virgin PLA during extrusion, which helps reinforce its properties and maintain print quality. Another approach is to use chemical additives known as chain extenders, which can help repair broken molecular links and restore mechanical strength. Consistent filtering of contaminants—like dust, pigments, or degraded bits—also plays a key role in preserving quality across cycles.

Finally, even when PLA can no longer be used for precision prints, it doesn’t have to go to waste. It can be downcycled into simpler, lower-load items such as small toys, organizers, planters, or promotional products where strength and durability are less critical. By understanding the limitations of PLA and applying thoughtful workarounds, we can keep plastic in use longer, reduce waste, and move closer to a truly circular lifecycle.

Help us protect and preserve for future generations

Join us and make the planet a better place.